How to standardize and scale transport in the global supply chain

In 2024, EU road freight transport recorded an increase of 0.6%, reaching 1,869 billion tonne-kilometers. This is a clear signal of the end of the downward trends of previous years and the related recovery of transport volumes. At the same time, the market is observing the intensification of logistics processes, which in Europe, however, takes place in conditions of significant systemic complexity.

Modern supply chains operate in an environment of unprecedented uncertainty. Data from 2024 shows a 38% increase in supply chain disruptions compared to the previous year, which is a clear signal that traditional transport management models require a fundamental transformation

Particularly worrying are the data on the visibility of supply chains: only 6% of companies achieve full transparency of their operations, and 62% of companies declare limited visibility to only 1-2 stages in their supply chain (they see only their direct suppliers and possibly their suppliers’ suppliers). Data is processed manually, exchanged in incompatible formats, and systems – from warehouse to transport – rarely communicate with each other smoothly.

This problem is exacerbated in the context of the growing complexity of international logistics operations, where a single load can “pass” through a dozen different systems, each with its own standards and data formats (e.g. carrier systems, freight forwarders, customs platforms, goods monitoring systems, warehouse systems, order platforms, transport documentation systems, EDI, etc.).

The lack of unified process standards and the growing regulatory requirements related to ESG and digitization pose a significant threat to the efficiency of logistics in Europe. This is especially true for industries such as FMCG and retail, which are characterized by strong seasonality. In this reality, it is no longer enough to scale up activities simply – it is necessary to standardize them to ensure process compliance with a dynamically changing legal, technological, and market environment.

Fragmentation and standardization of logistics processes

The lack of unified standards in global logistics generates huge hidden costs. Every time a load crosses a technological border (between different TMS, WMS or ERP systems), manual data conversion is required, which results not only in longer operation times but also in a significant increase in the risk of errors and data loss.

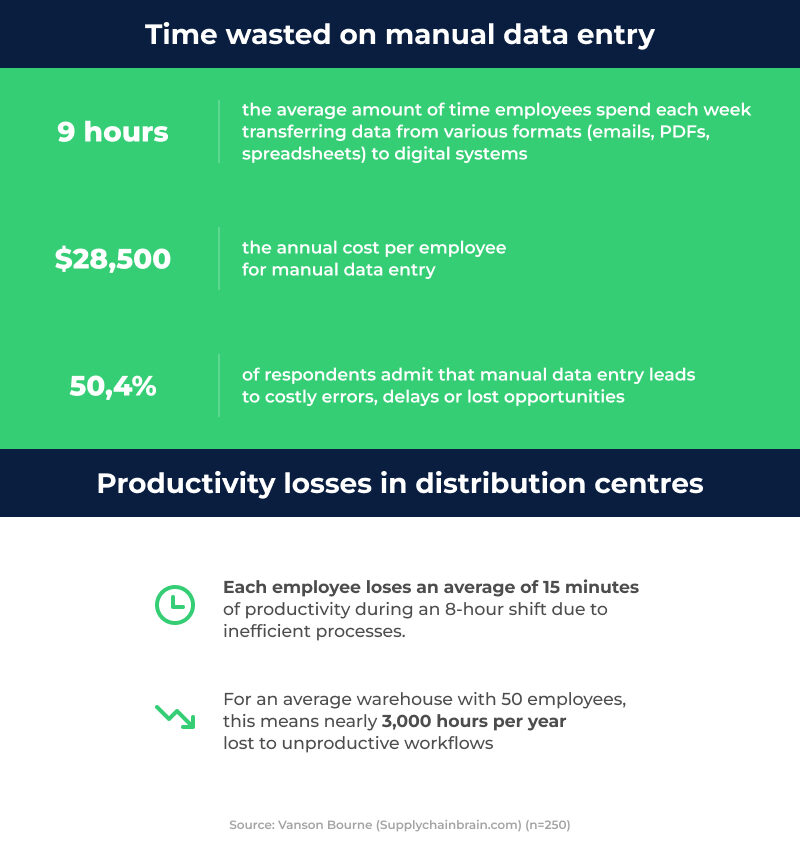

Research conducted among American companies shows that employees spend an average of more than 9 hours a week transferring data from various formats (emails, PDFs, spreadsheets) to digital systems. Manual data entry costs companies an average of $28,500 per employee per year. Half of the respondents admit that manual data entry leads to costly errors and delays.

The solution to excessive fragmentation of logistics processes is comprehensive standardization of data and communication, and operation management systems. EDI and GS1 standards have been the foundation of electronic document exchange in logistics for decades, enabling companies to instantly automate basic processes. While these technologies are mature, they remain relevant as a historical context; modern challenges require more advanced solutions.

API and data integration from different sources

Modern integration relies on open API interfaces and SDKs (sets of tools and libraries that facilitate software development for specific platforms, operating systems, or programming languages) that allow TMS/WMS/ERP systems to exchange data in real-time. The exchange takes place in unified JSON or XML formats. APIs enable semantic interoperability, which ensures precise interpretation of exchanged data through metadata description standards. This means eliminating ambiguity in communication between systems.

The growing demand for real-time analytics and digital transformation is driving the growth of global API adoption. The global API market is estimated to grow from $6.89 billion in 2025 to $32.77 billion by 2032, with a compound annual growth rate (CAGR) of 25%. It is worth noting that transport and logistics are a significant segment of this market. Why?

APIs in the transport sector provide access to functions related to the delivery of goods, such as rate calculation, label printing, bill of lading generation, and real-time delivery tracking. The API for logistics focuses on even broader functions such as inventory listing, transport management, and order processing.

Benefits of API integration in logistics

1. Access to carrier networks and 3PL services: API integration enables direct connections with external carriers and logistics operators (3PL), facilitating the rapid deployment of new transport services within existing systems.

2. Reduction of operational costs: Through the automation of repetitive tasks such as manual data entry, label generation, freight comparison, and delivery optimization, significant reductions in administrative costs and human errors can be achieved.

3. Enhanced operational transparency: Modern APIs allow for real-time tracking of loads, inventory monitoring, and order management, leading to greater control and improved planning of logistics activities.

4. Scalability of logistics processes: API solutions enable easy expansion of product ranges, geographic reach, and delivery options without the need to overhaul existing IT infrastructure.

5. Reduced risk of legal errors: Many API tools offer automatic label generation and transport documentation features, reducing the risk of regulatory non-compliance and associated penalties.

Summary

Fragmentation of systems and lack of unified data exchange standards are among the key challenges in logistics today. Manual information processing generates enormous costs, reduces productivity, and limits visibility of operations in the supply chain.

The solution is to transition from fragmented, inconsistent systems to integrated environments based on open API interfaces. These enable scalability, automation, and full operational transparency – key elements in modern, resilient, and ESG-compliant logistics.

Companies that focus on standardization and interoperability will gain a competitive advantage in an increasingly digital and regulated business environment.

—

References

-

Eurostat, EU road freight transport sees 0.6% increase in 2024, 9 lipca 2025 r., https://ec.europa.eu/eurostat/web/products-eurostat-news/w/ddn-20250709-1?utm_source=chatgpt.com, accessed: 18.08.2025

-

Resilinc, Resilinc Reveals the Top 5 Supply Chain Disruptions of 2024, 23 stycznia 2025 r., https://resilinc.ai/blog/resilinc-reveals-the-top-5-supply-chain-disruptions-of-2024/, accessed: 18.08.2025

-

Geodis, Operating resilient supply chains, 2020 activity and corporate social responsibility report, 2020, https://geodis.com/sites/default/files/2021-07/GEODIS%20RA_RSE_2020_UK.pdf, accessed: 18.08.2025

-

Geodis, Supply Chain worldwide survey, 2017, https://geodis.com/sites/default/files/2019-03/170509_GEODIS_WHITE-PAPER.PDF, accessed: 18.08.2025

-

Johnson E., Logistics’ fragmentation inclination, 7 maja 2021 r., https://ericjohnson.substack.com/p/logistics-fragmentation-inclination, accessed: 18.08.2025

-

Gunnoo N., Manual Data Entry Costs U.S. Companies $28,500 Per Employee Each Year, 29 lipca 2025 r., https://parseur.com/blog/manual-data-entry-report, accessed: 18.08.2025

-

SupplyChainBrain, Distribution Centers Lose Nearly 3,000 Hours a Year on Unproductive Workflows, Study Says, 4 grudnia 2012, https://www.supplychainbrain.com/articles/14950-distribution-centers-lose-nearly-3000-hours-a-year-on-unproductive-workflows-study-says, accessed: 18.08.2025

-

Slisarenko R., How To Integrate Logistics API and Shipping API Efficiently, 5 czerwca 2024 r., https://tech-stack.com/blog/shipping-api/, accessed: 18.08.2025